Control System

Integration

Technical Services to Complement Your Automation Project

We provide a broad offering of technical services to complement your automation project. Our experience and knowledge allows us to guide you through a process of defining the over-all system or machine critical performance requirements, followed by a more detailed sequence of operation along with alarm and data collection. We also have the capability of designing in proper safety circuits from your analysis of required SIL levels.

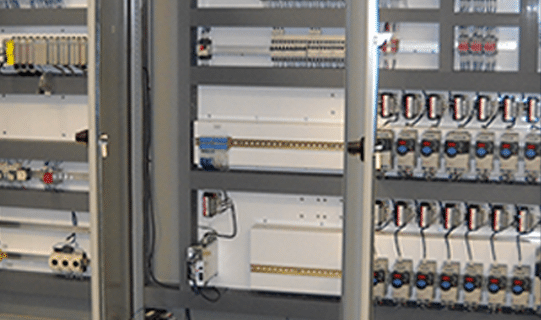

Labor & Industry safety requirements for electrical control systems continue to evolve and be more challenging for our customers to navigate. Our knowledge of NFPA and UL/cUL in the areas of component selection, circuit protection, proper component spacing arrangements, wiring practices and the correct application of safety circuit components are just a few of the critical areas that we help clients maintain statutory compliance.

Control System

Integration

Technical Services to Complement Your Automation Project

We provide a broad offering of technical services to complement your automation project. Our experience and knowledge allows us to guide you through a process of defining the over-all system or machine critical performance requirements, followed by a more detailed sequence of operation along with alarm and data collection. We also have the capability of designing in proper safety circuits from your analysis of required SIL levels.

Labor & Industry safety requirements for electrical control systems continue to evolve and be more challenging for our customers to navigate. Our knowledge of NFPA and UL/cUL in the areas of component selection, circuit protection, proper component spacing arrangements, wiring practices and the correct application of safety circuit components are just a few of the critical areas that we help clients maintain statutory compliance.

New Equipment Design

Our projects involve new equipment design, as well as upgrading legacy systems to new platforms of PLC, HMI and networking technology. The majority of the upgrades that we have experience with now incorporate bus technology (i.e. Ethernet) to communicate with HMIs, motor drives and even other control systems.

From Concept to Completion

Our application experience is both on the raw materials side of the plant, as well as the materials handling & packaging. From “concept to completion” we are here to navigate every detail to successfully complete your project.

- New Equipment Concept Study & Budget

- Existing Equipment As-Built Analysis & Drawings

- Functional & Design Specifications

- Control Panel Design & Component Arrangement

- Factory Floor Network Architecture Design

- Electrical Power & Control Wiring Schematics

- Component Selection & Bill of Materials

- Enclosure Fabrication Design Drawings

- PLC & HMI Program Development

- Motor VFD Set-Up & Configuration

- Vision Camera Programming & Integration

- Collaborative Robot Arm Integration

- On-Site Start-Up & Commissioning

- Control System Installation Supervision

- Factory Acceptance Testing With In-House Simulation

- Operator & Maintenance Training

- Depth of experience in programming HMIs (Human Machine Interface) and PLCs (Programmable Logic Controller) is an absolute must in modern manufacturing. We work with all major PLC/HMI manufacturers, with focus on Rockwell (Allen Bradley), Siemens, GE, Modicon, Honeywell, Proface, Omron, etc. We are experts in designing and implementing safety controls applications.

- Trola’s inspection/rejection systems remove human error, reduce cycle times, and improve inspection accuracy. We offer comprehensive solutions that include 2D and 3D imaging capabilities, advanced data acquisition and processing, custom mounting design and fabrication, and integration with line and plant-wide systems.

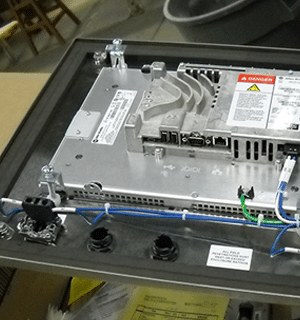

- Design engineering is a cornerstone of our mission to deliver efficient and reliable solutions. With expertise in UL508a control panel design and a proven track record of retrofitting legacy equipment with modern controls, we offer cost-effective solutions that minimize downtime and enhance operational efficiency.

- From electricians and mechanics to IT, OEMs and plumbers, we take charge of the entire project, leveraging our expertise to seamlessly coordinate with other suppliers. By entrusting us with the task of managing your line or area startup, we ensure end-to-end oversight, control, and on-time delivery of your projects.

- Whether it’s providing real-time updates on product location, enablement of real-time detection of personnel or objects in safety systems, or alerting us to potential issues like motor overheating, our expertise in instrument and sensor integration guarantees your operations run smoothly and efficiently.

Areas of Operation

- New Equipment Concept Study & Budget

- Existing Equipment As-Built Analysis & Drawings

- Functional & Design Specifications

- Control Panel Design & Component Arrangement

- Factory Floor Network Architecture Design

- Electrical Power & Control Wiring Schematics

- Component Selection & Bill of Materials

- Enclosure Fabrication Design Drawings

- PLC & HMI Program Development

- Motor VFD Set-Up & Configuration

- Vision Camera Programming & Integration

- Collaborative Robot Arm Integration

- On-Site Start-Up & Commissioning

- Control System Installation Supervision

- Factory Acceptance Testing With In-House Simulation

- Operator & Maintenance Training

HMI/PLC/VFD Programming

- Depth of experience in programming HMIs (Human Machine Interface) and PLCs (Programmable Logic Controller) is an absolute must in modern manufacturing. We work with all major PLC/HMI manufacturers, with focus on Rockwell (Allen Bradley), Siemens, GE, Modicon, Honeywell, Proface, Omron, etc. We are experts in designing and implementing safety controls applications.

Machine Vision Inspection/Rejection Design

- Trola’s inspection/rejection systems remove human error, reduce cycle times, and improve inspection accuracy. We offer comprehensive solutions that include 2D and 3D imaging capabilities, advanced data acquisition and processing, custom mounting design and fabrication, and integration with line and plant-wide systems.

Design Engineering - New/Retrofit

- Design engineering is a cornerstone of our mission to deliver efficient and reliable solutions. With expertise in UL508a control panel design and a proven track record of retrofitting legacy equipment with modern controls, we offer cost-effective solutions that minimize downtime and enhance operational efficiency.

Production Line Construction Management

- From electricians and mechanics to IT, OEMs and plumbers, we take charge of the entire project, leveraging our expertise to seamlessly coordinate with other suppliers. By entrusting us with the task of managing your line or area startup, we ensure end-to-end oversight, control, and on-time delivery of your projects.

Process Instrumentation & Sensor Integration

- Whether it’s providing real-time updates on product location, enablement of real-time detection of personnel or objects in safety systems, or alerting us to potential issues like motor overheating, our expertise in instrument and sensor integration guarantees your operations run smoothly and efficiently.

Ready to Connect?

Let's Get Started